CASE STUDY TechDraw FT 400: Formulation Eliminates Cracks and Rust

Background:

A leading metal stamper serving the automotive, industrial, appliance and recreational vehicle industries was experiencing splitting of some critical components, rusting during storage, as well as residue buildup on their dies and conveyors with their current synthetic drawing compound.

The Solution:

Fortech Products introduced them to TechDraw FT 400, Fortech’s flagship semi-synthetic, which carries numerous automotive OEM approvals and is notably a very clean-running product. The business case supporting the performance characteristics and the projected spend of the fluid enticed the customer to run several trials before expanding to all 15 presses. Being multi-metal compatible, the customer was able to push the limits of the fluid in many scenarios across the plant from the central mix station.

Benefits and Features of TechDraw FT 400

✔ OEM Body-in-White approved

✔ Provides excellent lubricating properties that protect parts and tooling

✔ May be applied to all coated or non-coated substrates

✔ Imparts in-process corrosion protection

✔ Non-pigmented, no chlorine or sulfur

✔ Parts can go from stamping to welding or paint pre-treatment without supplemental washing

✔ For ease of mixing and application, TechDraw FT 400

can be offered pre-diluted

The Result:

The trial surpassed expectations. TechDraw FT400 exceeded all challenges successfully with profitable results. The customer has improved performance with documented process savings.

Splits: Previous fluid in red resulted in typically 60 out of 5,000 splits, TechDraw FT400 has yet to produce a split.

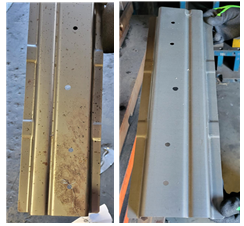

Rust: Both parts processed and stored in the same conditions. The part on the left clearly rusted with previous fluid.

Cleanliness: Operators and 3rd party conveyor maintenance all agree the process is much cleaner now with no gummy residues.